Wave and selective soldering are critical joining processes in modern electronics, where product reliability depends on tight control of materials, heat, and motion. This article shares Top 10 Wave and Selective Soldering Best Practices in Electronics to help engineers, technicians, and quality teams improve yields with confidence. You will learn practical methods that reduce bridges, icicles, voids, and non wetting while protecting sensitive components. Each practice connects setup decisions to measurable outcomes and supports repeatable production. Follow these guidelines to build a stable, data driven workflow that scales from prototypes to high volume production. Results arrive faster and with minimal surprises.

#1 Design for process readiness

Plan pad geometries, solder masks, hole sizes, and clearances to fit the chosen process. For wave, orient leads to trail the wave for smooth peel off. For selective, group pins by thermal mass and keep tall shields away from nozzle paths. Add thieving pads and copper breaks to pull solder and reduce bridges. Provide palette keep outs for sensors and plastics, with drill hits for repeatable registration. Validate with simple experiments that pad and hole sets deliver consistent hole fill, then share lessons with layout teams for future spins. Document the rules in the drawing notes.

#2 Control flux chemistry and deposition

Match flux type to board finish, component metallurgy, and cleanliness goals. Track solids by titration or density and align spray settings to deliver an even, thin, activated film. Verify coverage under components with ultraviolet inspection on complex palettes. Set conveyor speed so solvent evaporates without scorching. For selective, tune drop jet timing to avoid puddling in vias. Keep reservoirs sealed to limit solvent loss. Audit each shift and link alarms to drift so operators correct early. Calibrate spray heads and replace worn tips that streak coverage. Record lot numbers to aid traceability.

#3 Preheat to the right topside temperature

Preheat drives solvent evaporation, activates flux, and reduces thermal shock. Monitor topside temperature with contact thermocouples near heaviest pins and ground planes. Aim for a steady soak that reaches the activation window without overheating laminates or plastics. Balance infrared and convection zones to avoid overshoot at copper rich areas. For selective, use localized preheat to shorten dwell and curb voids. Recheck after maintenance and record profiles by lot number. Validate with coupons that wetting improves at the chosen targets. Add insulating covers on palettes when heavy sinks steal energy and slow ramp.

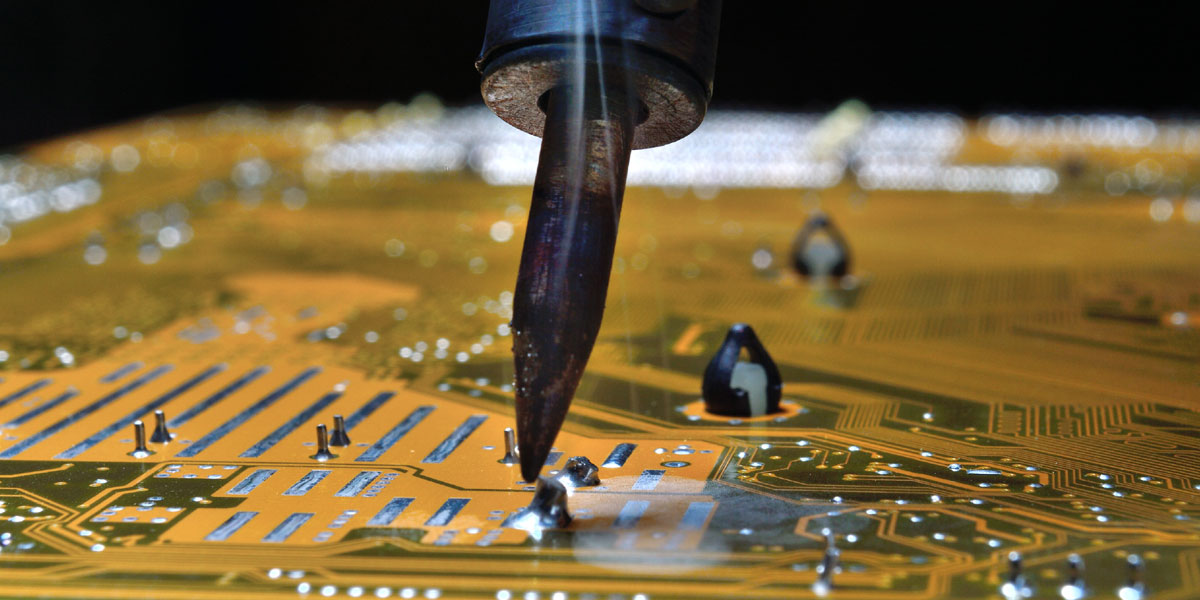

#4 Optimize wave parameters

Set conveyor angle, immersion depth, and contact length to achieve consistent fillet formation. Run process windows using test vehicles to map safe ranges and center the recipe. Use laminar wave for overall wetting and a chip wave for fine pitch defects when needed. Limit vibration that tears fillets and polish fingers to stabilize contact. Adjust peel off to prevent icicles and shorts. For mixed technology boards, schedule a double pass that targets heavy pins first, then delicate areas with shorter dwell. Confirm hole fill and intermetallic thickness with cross sections, and keep golden recipes under change control.

#5 Master selective nozzle choice and pathing

Choose nozzle diameter to match lead pitch and thermal mass, then tune stand off and approach angle for smooth flow. Program paths that avoid crossing previously soldered pins while the joint is fluid. Use entry ramps and exit dwells to manage peel, and add brief cooling hops between nearby joints. Sequence high mass connectors earlier, followed by smaller groups that need shorter contact. Add keep away rules for tall heat sinks that deflect flow. Periodically review programs against the defect pareto so motion stays optimized. Validate by measuring contact time at each pin with a stopwatch and camera.

#6 Maintain solder alloy health and pot stability

Track copper and nickel pickup with spectro or wet chemistry checks, and schedule dross removal that does not entrain oxides back into the pot. Skim gently and add clean ingots to restore composition. Use covered pots and inert blankets to reduce oxidation. Log actual solder temperature with independent probes and verify controller offsets. For selective, flush recirculation filters to protect pumps and nozzles. Install interlocks that stop production when temperature or composition drift past limits. Keep service logs for pumps, heaters, and sensors. Replace old alloy when impurity limits approach specifications that threaten wetting quality.

#7 Manage nitrogen and atmosphere quality

Inerting improves wetting, reduces bridging, and lowers dross formation. Measure oxygen level at the wave surface and at the selective solder head, not only at a remote sensor. Tune nitrogen flow to hold the target range without turbulence that disturbs fillets. Check curtain integrity, door seals, and exhaust balance so ambient air does not leak in. Capture oxygen trends alongside defect rates to show the benefit. Train maintenance to restore targets quickly after door openings and planned service. Use simple smoke tests to visualize drafts, and verify recovery time after panels enter the enclosure.

#8 Engineer palettes and fixturing

Fixtures protect parts from the wave, support thin boards, and stabilize thermal conditions. Select high temperature materials with low wear and predictable expansion. Provide drain channels that prevent solder pooling near tall components. Add datum features to ensure repeatable placement and conveyor engagement. For selective, include cutouts that let preheat reach target pins while shielding plastics. Bake new palettes to drive off volatiles before use, then measure flatness. Inspect edges often and resurface worn areas that trap solder. Use go and no go gauges to verify palette thickness and squareness during preventative maintenance.

#9 Cleanliness and board preparation

Incoming boards should meet ionic and visual standards that match flux activity. Remove handling oils with controlled wipes or pre clean modules when residues exceed limits. Keep leads free from oxidation by managing storage environment and using first in first out rules. Handle assemblies with gloves to prevent fingerprints that hinder wetting. Ensure thermal relief patterns are correct to avoid heat sinking problems during rework. Store panels in dry cabinets when finishes are moisture sensitive, and verify solderability with dip and look coupons for each lot. Clean carriers regularly so flux residues do not redeposit.

#10 Inspect, measure, and close the loop

Define acceptability with measurable criteria such as fillet height, wetting angle, pin coverage, and void content. Use AOI where geometry allows and X ray for dense connectors or void studies. Calibrate visual inspection with gauge studies so judgments are consistent. Build a defect pareto and relate each category to inputs like flux load, contact time, oxygen level, and preheat. Employ SPC on temperatures and conveyor speed, then review dashboards in daily stand ups. Update work instructions and training after each improvement so gains stick. Share wins with suppliers to strengthen the entire supply chain.