Surface mount technology has transformed how electronic products are designed, assembled, and scaled, enabling smaller footprints, higher speeds, and reliable automation across industries. This article explains the Top 10 Surface Mount Technology Advances for Electronics Manufacturing for readers at every level. You will learn how equipment, materials, processes, and data practices work together to raise yield and quality while controlling cost. Each advance outlines what it is, why it matters, and where it applies so learners and experienced engineers benefit. By the end, you will have a compact guide that connects machine capability with design, factory analytics, and sustainability for modern electronics.

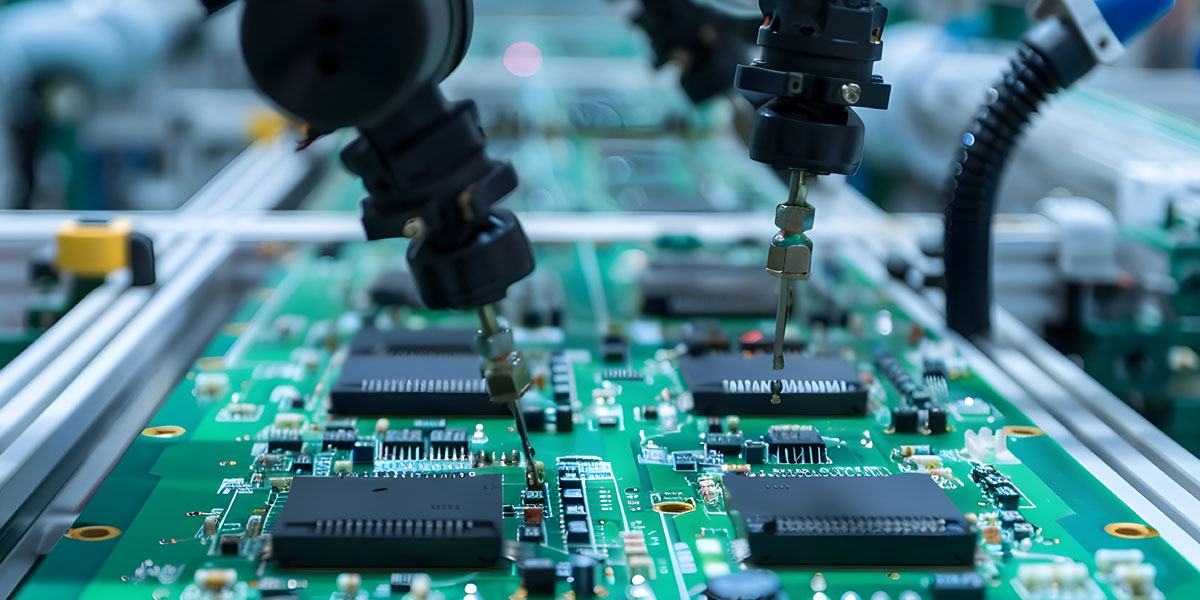

#1 High speed pick and place with AI vision

High speed pick and place platforms now combine linear motors, advanced feeders, and multi nozzle heads with AI assisted vision to reach astonishing placements per hour without sacrificing accuracy. Inline cameras classify components, compensate for shadowing, and auto tune lighting for matte, glossy, or black packages. Adaptive tact control matches board complexity, reducing idle time and improving throughput on mixed lots. Closed loop correction uses fiducials, corner features, and dynamic board warp models to maintain placement within tight tolerances. The result is higher productivity for prototyping, automotive, industrial, and consumer boards that demand both speed and repeatable precision.

#2 Jetting and micro volume dispensing

Jetting and micro volume dispensing have expanded solder paste and adhesive deposition far beyond stencil printing. Modern piezo and pneumatic jet valves place controllable droplets at kilohertz rates, enabling fine pitch pads, edge pads, cavities, and glue dots without contact. True volume control is achieved with closed loop mass measurement and in situ imaging that verifies dot diameter and roundness. Jet recipes adjust to paste rheology, particle size, and temperature. This flexibility shortens changeovers, supports non planar boards, and reduces defects like bridging or insufficient deposits for high density designs. Engineers can tune deposits per pad to improve reliability on power and RF assemblies.

#3 Next generation solder paste printing

Solder paste printing has advanced through step stencils, nano coated apertures, and automated understencil cleaning that keeps apertures open on long runs. Smart printers use 3D solder paste inspection and machine learning to tune squeegee pressure, speed, and separation based on live height maps. Closed loop feedback corrects offset, warpage, and smear before boards leave the printer. Automatic paste kneading and temperature control stabilize viscosity, extending open time and reducing dross. Together these features deliver consistent paste height and area, enabling fine pitch, micro BGA, and 01005 component printing with fewer rework cycles and stronger first pass yield.

#4 SPI and AOI as active process controllers

SPI and AOI systems have become central process controllers rather than end of line checkers. Modern optics deliver multi angle, multi color lighting and telecentric lenses to resolve tiny meniscus shapes, tombstones, and head in pillow signatures. Algorithms fuse two dimensional textures with three dimensional height to detect solder volume, fillet quality, and coplanarity. Defect data flows upstream to printers and placers to correct root causes automatically within the same shift. False calls drop through better libraries, golden panels, and synthetic images that improve classifier confidence on new products while preserving escape rates for safety critical markets.

#5 Precision reflow with vacuum and digital twins

Reflow ovens now feature precise thermal zoning, vacuum options, and real time oxygen monitoring to shape solder joints for reliability. Advanced convection profiles combine soak, ramp, and peaking strategies with nitrogen control to limit voiding and intermetallic growth. Vacuum reflow removes entrapped gases in bottom terminated components and power packages to reduce porosity. Digital twins simulate board thermal mass, copper density, and component height to predict delta T across the panel and guide recipe creation. Inline profilers and recipe guards keep runs within a proven process window, minimizing defects and energy use over long production campaigns.

#6 Connected line software and predictive analytics

Factory software has embraced open interfaces that unify machine data from printers, placers, ovens, and inspectors. Standardized messages map feeder errors, nozzle health, paste status, and defect trends onto dashboards that operators can act on in real time. Rules engines trigger stops, recipe changes, or maintenance tasks when thresholds are crossed. Predictive models forecast nozzle clogging and feeder wear based on cycles and material history, improving spare parts planning. This connected line approach reduces unplanned downtime and supports lights out operation for repeatable products and small lot agility with consistent quality. APIs also simplify integration with enterprise systems for costs, genealogy, and compliance reporting.

#7 Part and board level traceability

Component and board traceability has matured from basic barcodes to item level tracking. Unique identifiers follow reels, cut tape, trays, and PCBs through receiving, kitting, placement, and reflow. Tie in with enterprise systems enables material genealogy for every serial number and complete lot history. Cameras confirm lot codes and avoid part mix during changeovers with automatic validation on feeders. When a field failure occurs, suspect range analysis isolates exactly which assemblies and lots are affected, shrinking recall scope and speeding corrective action for regulated markets. This precision also streamlines warranty handling, supplier audits, and counterfeit risk mitigation.

#8 Advanced pastes, adhesives, and protective materials

Advanced materials are improving yields and long term reliability. Low voiding pastes use optimized flux systems that outgas cleanly, while Type 5 and Type 6 powders support ultra fine pitch. Conductive and non conductive adhesives meet thermal and mechanical needs for flex and rigid flex assemblies. High temperature laminates and surface finishes like ENEPIG balance solderability with wire bond and gold needs. Underfills, corner bonds, and conformal coatings are now dispensed inline with precise cure monitoring to protect fragile packages during shock, vibration, and humidity exposure. Material selection is guided by reliability testing that links microstructure to field performance.

#9 Data driven design for manufacturability

Design for manufacturability has become a data driven partnership between CAD and the factory. Bidirectional formats carry component heights, keepouts, fiducials, and test points from design into programming without translation errors. DFM analyzers flag tombstoning risks, paste starvation, and thermal imbalances before fab using physics based rules. Panelization optimizes breakaway tabs, rail widths, and fiducial placement for stable transport and accurate warpage control. Early collaboration shortens new product introduction cycles and prevents costly redesigns after pilot builds. The payoff is faster ramps with higher first pass yield and smoother transitions from prototypes to volume manufacturing.

#10 Sustainability and humane workcells

Sustainability in SMT now focuses on energy, waste, and operator wellness without compromising performance. Low energy reflow recipes, smart standby modes, and heat recovery cut kilowatt hours per panel in measurable steps. Paste life tracking and right sized cartridges reduce scrap and improve inventory turns. Waterless stencil cleaning chemistries and closed loop solvent recovery lessen environmental impact while maintaining print quality. Workcell ergonomics, noise reduction, and clearer HMIs support safe, efficient operation for diverse teams. Suppliers provide carbon data for materials and equipment, enabling factories to set targets, audit progress, and publish credible sustainability reports alongside traditional quality metrics.