Soldering is the backbone of reliable electronics, joining components to printed circuit boards with a blend of science and craft. In this guide, we walk learners from basics to advanced practice, focusing on process control, safety, and repeatability. You will see how heat sources, flux chemistries, and joint designs shape performance, costs, and yields. We also highlight inspection cues and common mistakes to avoid. Together, these sections form a practical map of the Top 10 Soldering Techniques in Electronics Assembly, with concise explanations and selection criteria. By the end, you will know when to use each technique and how to tune parameters for consistent quality.

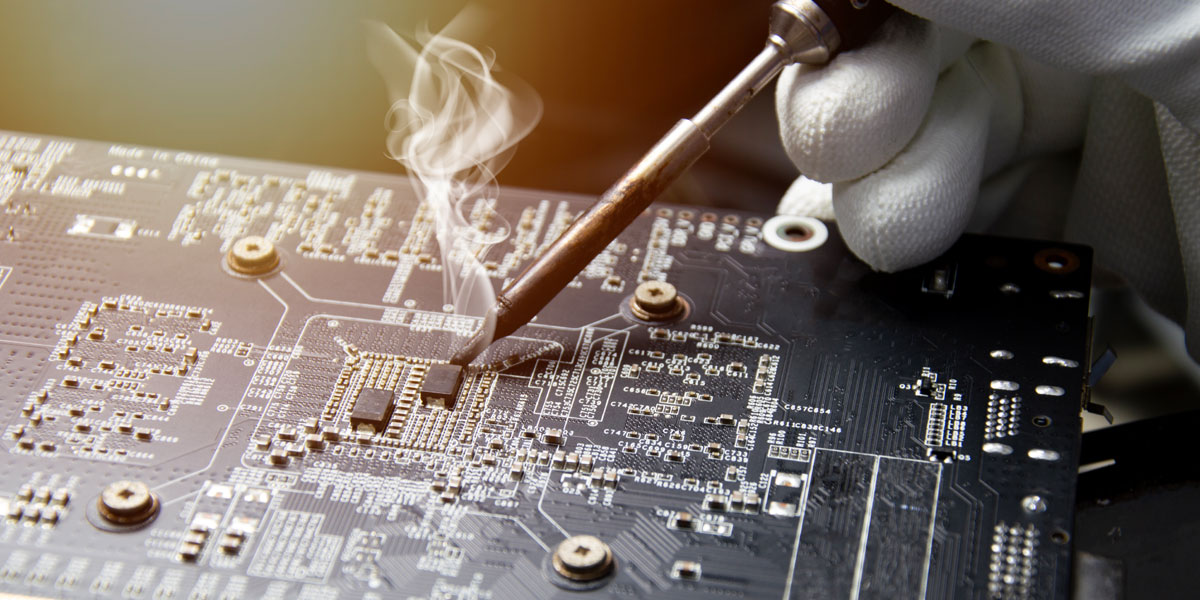

#1 Temperature-Controlled Hand Soldering

Hand soldering with a temperature-controlled iron remains the most versatile method for prototypes, repairs, and small batches. Use a tip shape matched to pad geometry, keep the iron between 320 and 370 degrees Celsius for leaded alloys, and adjust higher for lead-free. Apply flux first, heat the joint, then feed solder to the work, not the tip. Clean and tin the tip often to maintain thermal transfer. Train operators to watch wetting angles and fillet shape, and to avoid lifting pads. Document tip care, dwell time targets, and ESD practices to ensure consistent quality.

#2 Convection Reflow Soldering

Convection reflow is the standard for surface mount assemblies, using profiled heat to reflow solder paste printed through a metal stencil. Build a profile with preheat, soak, time above liquidus, and controlled cooling, then verify with thermocouples and attached dataloggers. Paste selection matters, including alloy, flux type, metal load, and particle size. Design pads with proper aperture reductions to control paste volume and minimize tombstoning. Use nitrogen when oxidation or fine pitch drive tighter process windows. Inspect with automated optical inspection to confirm wetting, fillet symmetry, and component alignment across the panel.

#3 Wave Soldering

Wave soldering excels for through-hole boards and mixed technology assemblies that require top-side reflow plus bottom-side solder fill. Control the preheat to activate flux and prevent thermal shock, then set conveyor speed, immersion depth, and dwell time for full barrel fill. Select flux type and application method carefully to balance wetting and residue. Use pallets or peelable masks to shield surface mount areas. Adjust chip wave and laminar wave settings to address bridging and icicles. Confirm results with cross-sections and hole fill metrics, targeting industry standards for fill percentage and visual acceptance.

#4 Selective Soldering

Selective soldering uses mini waves or dip nozzles to solder specific through-hole pins while protecting nearby surface mount parts. It is ideal for dense boards and thermally sensitive devices. Program precise path motions, lead angles, and dwell times, and synchronize flux spray and preheat. Use dedicated tooling to ensure planarity and to maintain keep-out distances. Fine-tune nitrogen flow to improve wetting and reduce dross. Validate with hole fill, solder meniscus shape, and topside fillet presence. Record recipes by part number so repeat builds achieve the same wetting behavior and yields. Use SPC charts to monitor fill and defect trends lot to lot.

#5 Vapor Phase Reflow

Vapor phase reflow uses a boiling inert fluid to transfer heat uniformly at a fixed peak temperature, reducing hot spots and oxidation. It is valuable for heavy boards, large thermal masses, and low voiding in power packages. Control the preheat ramp and peak dwell to avoid component float or flux spitting. Use carriers to manage condensate runoff and to keep labels intact. Choose fluid grades with appropriate boiling points for the alloy in use. Measure voiding with X-ray and tune paste, stencil apertures, and vacuum assist settings to reach reliable thermal and electrical performance.

#6 Hot Air Rework and BGA Reballing

Hot air rework stations enable precise component removal and replacement, especially for QFN and BGA devices. Create a localized reflow profile using preheaters and controllable nozzles to avoid collateral heating. Use solder wick and low-residue flux to clear pads, then place parts with vision alignment. For BGA, inspect with X-ray to confirm collapse and void levels; use site redress stencils to restore pad planarity. Control peak temperatures and time above liquidus to protect underfill or nearby plastic. Document rework windows and acceptance criteria so field returns and prototypes receive consistent treatment.

#7 Drag Soldering for Fine Pitch

Drag soldering speeds up hand work on fine-pitch gull-wing leads and headers. After applying flux, load a small solder bead on a chisel tip and gently drag along the row, letting surface tension form even fillets. Use solder mask dams and correct tip angle to prevent bridges. Wick away excess with desolder braid, then clean residues as required by flux type. Practice is essential, so set up scrap boards for training and capture video of ideal technique. Inspect with magnification to verify toe, heel, and side fillet quality at every lead.

#8 Laser Soldering

Laser soldering delivers targeted, rapid heating without contacting the work, useful for micro parts, flex circuits, and shield seams. Integrate vision to aim the beam, and use feedback such as pyrometry to control energy delivery. Preform or paste can supply solder; flux choice must match the substrate and cleanliness goals. Program spot sizes, dwell patterns, and step-and-repeat motions for uniform fillets. Enclose the cell for laser safety and fume extraction. Validate with pull testing and metallographic cross-sections to confirm intermetallic growth, wetting, and heat affected zones remain within limits. Track energy and spot records to support traceability in regulated industries.

#9 Hot Bar Soldering

Hot bar, also called thermode soldering, uses a heated tool under force to join flex to rigid boards, connectors, or wires. Control three parameters at once: temperature, time, and pressure. Design joint geometry and use preforms or tinned pads to standardize solder volume. Use fixtures to align parts and to prevent part shift during heating. Ramp down force during cooling to reduce voids and stress. Record force and temperature traces for each cycle to prove repeatability. This technique shines in high mix, medium volume assemblies and where clean, fluxless processes are preferred.

#10 Ultrasonic Soldering

Ultrasonic soldering introduces acoustic energy into molten solder to disrupt oxides and enable bonding to glass, ceramics, and some aluminum without flux. Use compatible active solders or metallized surfaces for best wetting. Control sonication time and power to avoid substrate damage, and keep bath temperature stable. Because flux is minimized, cleanliness and surface preparation are critical. This method is valuable for sensors, optoelectronics, and biomedical devices with strict residue limits. Validate adhesion with shear tests and thermal cycling, and document parameters to support repeatable bonds in specialized applications. Train technicians on acoustic hazards and on handling brittle materials during fixturing and transport.