Sheet metal forming turns flat stock into precise parts for vehicles, appliances, aircraft, and electronics. This guide explains fundamentals, capability limits, quality controls, and tooling choices so that beginners and practitioners can speak the same language. From low cost mass production to complex aerospace skins, you will learn where each process shines and where it struggles. We frame tolerances, springback, and formability in clear terms, with practical tips for design for manufacturing. The focus keywords are Top 10 Sheet Metal Forming Techniques Stamping Deep Drawing Hydroforming, which anchor the scope across classic presses and modern flexible forming cells.

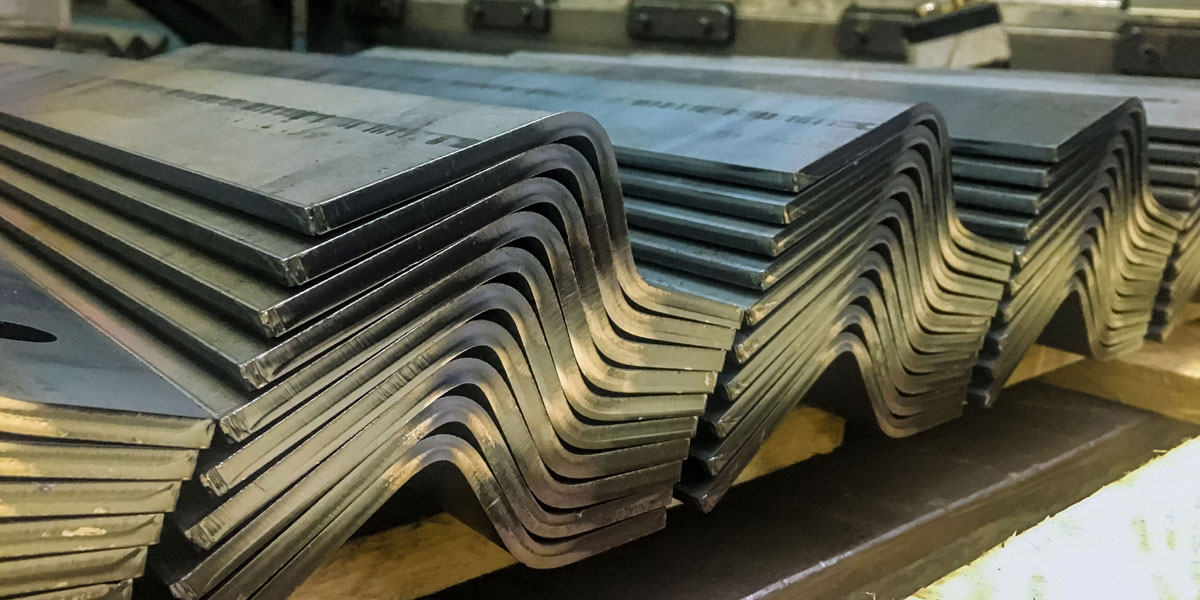

#1 Stamping

Stamping uses a press and matched dies to blank, pierce, coin, and form parts from coil or sheet. It delivers high speed and repeatability for brackets, covers, and electrical frames. Success depends on die steel selection, clearance, radii, and lubricant choice to control burr, galling, and wear. Engineers should add generous radii, avoid tight corners, and align grain direction to critical bends. Tryout shims and progressive dies reduce setup time for large volumes. Monitor tonnage, feed misalignments, and die temperature to prevent drift. For stable quality, combine in die sensors with statistical process control and planned maintenance.

#2 Deep drawing

Deep drawing stretches a blank into a cavity to make cups, cans, and housings with smooth walls. Key variables include blank holder force, draw bead geometry, punch nose radius, and lubrication to prevent wrinkling and tearing. Choose materials with high r value and uniform elongation for safer draw ratios. Add draw beads to feed metal smoothly, and use ironing to equalize wall thickness when required. Finite element simulation predicts thinning and failure, which shortens tryout. Anneal between draws for severe shapes. Quality checks track earing height, wall thinning, and surface finish to verify stability across coils and shifts.

#3 Hydroforming

Hydroforming replaces a hard die half with pressurized fluid that forces the sheet into a rigid cavity. The fluid support lowers friction and delays necking, which enables complex contours, sharp features, and reduced thinning. It is ideal for lightweight body panels, stiffeners, and architectural skins that demand crisp radii and high surface quality. Cycle times are slower than stamping, so production best fits medium volumes. Engineers control pressure curves, counter pressure, and blank holder force to avoid wrinkles. Tooling costs are moderate, and flexible bladders allow variant families. Flow marks and trapped air require careful venting and clean filtration.

#4 Roll forming

Roll forming bends continuous strip through a series of stations to create constant profile shapes with tight tolerance. It delivers excellent straightness and long lengths for rails, channels, mullions, and frames. Designers should sequence small angle changes over many passes to limit strain spikes and springback. Pre punching and in line cutting reduce secondary operations. High strength steels and aluminum extrusions are both workable with correct roll metallurgy and coolant strategy. Setups benefit from flower diagrams and digital twins to validate forming progression. Monitor twist, bow, and camber with inline lasers, then adjust roll gaps and side guides accordingly.

#5 Stretch forming

Stretch forming clamps the sheet and stretches it over a die, distributing strain to create smooth, springback stable skins. It is widely used for aircraft panels, train claddings, and architectural features where waviness and oil can are unacceptable. Because material is in tension, compressive wrinkles are minimized, but thinning must be tracked. Engineers adjust clamp locations, pre stretch amount, and draw path to balance strain. Age formable alloys respond well when formed during controlled heat cycles. Surface protection is critical, so use clean pads and compatible films. Quality verification maps strain with grids, checks thickness, and inspects gloss consistency across the panel.

#6 Press brake bending

Press brake bending forms discrete bends using punches and dies with air bend, bottoming, or coining strategies. It excels at flexible, low to medium volumes with rapid setup and programmable backgauges. Choose larger inside radii to reduce springback and cracking, especially for high strength steels and tempers. K factor, bend allowance, and grain direction strongly influence flat patterns, so use proven bend tables. Tool selection and die opening control tonnage and radius. For accuracy, use crowning, real time angle sensors, and staged tooling for multiple bends. Quality focuses on angle, flatness, burr, and scratch control, with fixture plans for downstream joining.

#7 Spinning

Spinning rotates a blank on a mandrel while rollers locally deform the metal to produce axisymmetric parts like cones and hemispheres. It is an efficient route for lighting reflectors, cookware, and aerospace nose caps in small to moderate volumes. Hand spinning is flexible; CNC spinning gives repeatability and combines trimming. Preforming with shallow draws can shorten cycle time and reduce thinning. Material choice affects work hardening, so plan intermediate anneals for difficult alloys. Tool path programming controls wall thickness and surface finish. Inspection should confirm runout, roundness, and thickness, while lubrication and roller polish protect cosmetic surfaces reliably.

#8 Incremental sheet forming

Incremental sheet forming uses a round tool that traces a toolpath, deforming the sheet locally without a matched die. It suits prototypes and customized parts where lead time and cost must be minimal. Single point methods need only a simple clamping frame; two point methods add a partial die for better accuracy. Formability can exceed conventional limits because strain is highly localized. However wall thickness reduction and scallop marks require attention. Choose step down size, tool diameter, and path strategy to balance accuracy, surface quality, and time. Digital simulation and in process measurement improve outcomes and reduce the need for rework.

#9 Superplastic forming

Superplastic forming inflates fine grained sheet at elevated temperature and very low strain rate to achieve extreme stretch without failure. It produces deep, complex panels with few or no joints, popular in aerospace and premium transport. Cycle times are long and tooling must withstand heat, so the process fits high value, lower volume parts. Gas pressure profiles and die temperature control strain rate and thinning. Alloys require careful pre processing to reach the needed grain size. Hybrid routes combine superplastic forming with diffusion bonding to create stiff, lightweight sandwich structures. Dimensional checks verify cavity fill, and hardness mapping confirms thermal history compliance.

#10 Hot forming and quenching

Hot forming and quenching heats boron steel blanks, forms them quickly in water cooled dies, and quenches in the tool to create martensitic strength. Automotive safety parts like pillars and bumpers use this route for high strength with precise shape. Blank design includes tailored tempering and local soft zones for later joining or flanging. Process control covers furnace soak, transfer time, die temperature, and quench rate to reach target hardness. Coatings protect from scale and hydrogen pickup. Alternate press hardening routes with direct or indirect forming handle pre pierced blanks. Testing tracks tensile properties, hardness, and distortion to validate repeatable crash performance.