Selecting the right board material is the foundation of dependable electronics that last in harsh real world conditions. The Top 10 PCB Materials and Substrates for High-Reliability Electronics give designers control over heat, signal integrity, mechanical stability, and long term durability. Each material behaves differently with temperature, moisture, vibration, and high frequency signals, so the best choice depends on mission profile and environment. This guide explains what each material is good at, where it struggles, and how manufacturers qualify it. You will learn practical selection tips on dielectric constant, loss, glass transition temperature, and coefficient of thermal expansion.

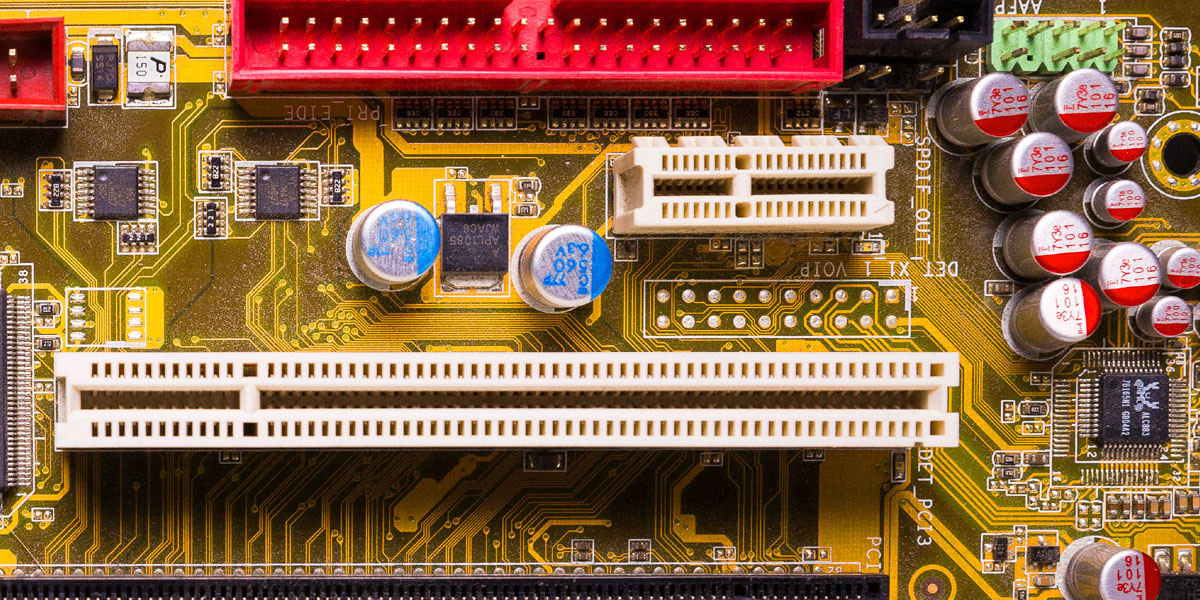

#1 High Tg FR-4 Epoxy Glass

High Tg FR-4 is the workhorse for reliable products that face moderate thermal stress, reflow cycles, and normal vibration. A higher glass transition temperature raises the softening point, which improves plated through hole integrity and limits resin recession during assembly. Stable dielectric properties support controlled impedance for many digital buses up to mid gigahertz. Moisture absorption is moderate and manageable with baking and dry storage. To maximize reliability, choose a variant with low Z axis expansion, compatible copper roughness for your loss targets, and proven CAF resistance. Validate with time above liquidus analysis and thermal stress coupons during qualification.

#2 Halogen Free FR-4 for Safety and Compliance

Halogen free FR-4 removes brominated flame retardants to meet environmental and smoke toxicity goals in transportation, consumer, and data center equipment. Modern halogen free systems use alternative resins and fillers that maintain flame retardancy while lowering corrosive off gassing during fire events. Electrical performance is similar to mainstream FR-4, with options for lower loss grades. Pay attention to resin brittleness and drilling behavior, since glass bundles and fillers can affect hole quality. For reliability, require proven CAF resistance, robust thermal shock performance, and repeatable solder mask adhesion. Reconfirm reflow profiles and pre conditioning because moisture handling can differ.

#3 Polyimide Laminates for High Temperature Endurance

Polyimide laminates excel when boards see continuous high temperatures, aggressive thermal cycling, or aerospace derating rules. The resin maintains mechanical integrity well above typical FR-4 limits, which protects copper barrels and microvias during assembly and service. Polyimide also shows strong chemical resistance, supporting harsh cleaning or conformal coating processes. The tradeoffs are higher cost, slightly higher dissipation factor in many grades, and care with moisture management. Specify low Z axis expansion and consider resin rich constructions around dense via fields. Use staged lamination cycles and controlled cool down to reduce residual stress that could drive barrel cracking.

#4 PTFE Ceramic Filled Laminates for RF Stability

PTFE ceramic filled laminates target microwave, radar, and 5G sub-6 designs where stable dielectric constant and low dissipation factor matter. Ceramic loading reduces thermal expansion and improves dimensional control, making hybrid builds with FR-4 cores more manageable. These materials offer tight Dk tolerance across temperature and humidity, aiding antenna matching and filter accuracy. Processing requires attention to surface preparation, because PTFE resists adhesion. Use treated copper, proper plasma cycles, and tailored lamination pressures. For reliability, verify via wall quality and choose fillers that balance drill life with low loss. Document solder reflow envelope to protect PTFE resin.

#5 Pure PTFE Woven Glass for Ultra Low Loss Links

Pure PTFE with woven glass reinforcement minimizes insertion loss for long high speed channels and millimeter wave circuits. It delivers very low dissipation factor and smooth copper interfaces that reduce conductor loss at high frequencies. The material is soft, so handling and lamination require discipline to control resin flow and thickness variation. Hole quality depends on sharp bits and proper chip evacuation, and surface activation is essential for adhesion. In high reliability builds, designers often combine PTFE signal layers with stiffer cores for rigidity and connector support. Validate with S-parameters across temperature to confirm stable channel budgets.

#6 Hydrocarbon Ceramic Low Loss Laminates

Hydrocarbon ceramic laminates provide a practical middle ground between FR-4 and PTFE. They deliver lower loss than FR-4, tighter Dk control, and easier processing than pure PTFE. The resin system bonds well to copper, drills cleanly, and supports hybrid stackups with standard prepregs, which reduces overall cost and complexity. These materials show improved thermal conductivity and lower Z axis expansion versus many epoxies, helping plated via reliability. They suit high speed digital backplanes, automotive radar, and mixed signal boards. For robust results, confirm compatibility of lamination cycles across all cores, and verify dimensional stability for fine pitch registration.

#7 Metal Core Aluminum for Power and LEDs

Aluminum metal core PCBs move heat efficiently from power devices and dense LED arrays into attached heat sinks and chassis. A thin dielectric with high thermal conductivity sits between the copper circuit and the aluminum plate, creating a short thermal path that lowers junction temperatures. The metal backbone raises stiffness, which protects solder joints during shock and vibration. Designers must manage isolation voltages, creepage, and differential expansion between copper and aluminum. Reliable assemblies use compliant thermal interfaces, proper torque control on fasteners, and solder alloys tuned for cycling. Plan for single sided routing or use insulated metal substrates for two layer needs.

#8 Copper Invar Copper and Low CTE Metal Cores

Copper Invar Copper and related low expansion metal hybrids stabilize the board against temperature swings that would otherwise strain solder joints and fine pitch components. Invar’s low coefficient of thermal expansion counters copper’s higher expansion, yielding a composite that tracks ceramic packages more closely. These cores improve flatness and reduce warpage during reflow, which supports large ball grid arrays and stacked memory. Fabrication requires careful lamination to bond the metal to dielectrics and to avoid resin starvation near edges. For reliability, coordinate stack symmetry, align stiffeners with component fields, and confirm drill parameters for consistent hole quality.

#9 Ceramic Substrates Alumina and Aluminum Nitride

Ceramic substrates deliver exceptional thermal performance and dimensional stability for high power and harsh environments. Alumina offers strong electrical insulation and good cost efficiency, while aluminum nitride provides much higher thermal conductivity for hot power modules. Direct bonded copper or thick film conductors create robust interconnects that survive repeated thermal cycling. Ceramics match the expansion of many power semiconductors, lowering solder fatigue. The tradeoffs are brittleness and limited multilayer capability. Use filleted solder joints, compliant attachments, and protective housings to manage shock. Qualification should include thermal shock, temperature humidity bias, and power cycling to confirm long service life.

#10 Flexible Polyimide and Rigid Flex Stackups

Flexible polyimide circuits and rigid flex stackups solve reliability problems caused by connectors and vibration by removing interconnects. The polyimide base film tolerates bending while keeping stable dielectric properties across temperature. Staggered microvias, tear stops, and dynamic bend radius rules prevent copper fatigue in motion zones. In rigid flex, the rigid sections support components and connectors, while flex arms route signals through tight volumes. Pay attention to coverlay openings, adhesiveless laminates for impedance control, and strain relief at transitions. Validate with dynamic flex testing, humidity soak, and thermal cycling. Properly designed rigid flex often raises overall system reliability substantially.