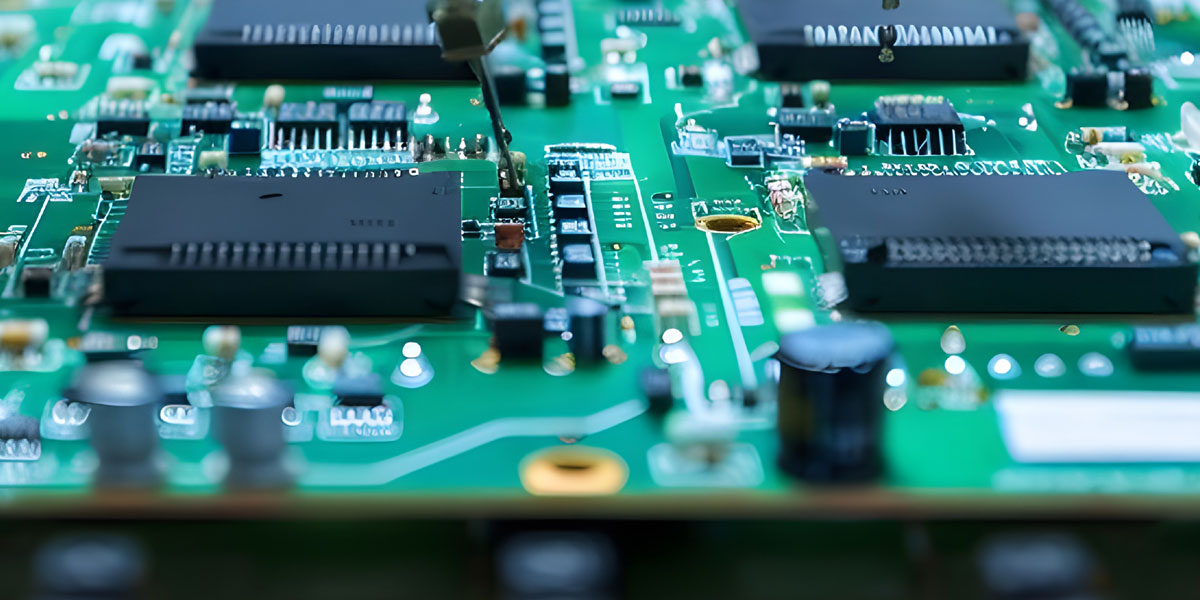

Printed circuit boards form the backbone of modern devices, and fabricating them with precision is essential for reliability, yield, and cost control. This article explains the Top 10 PCB Fabrication Processes for Electronics Manufacturing in a step by step way that helps both beginners and advanced readers. You will learn what each process does, why it matters, and how choices affect performance and time to market. The goal is to give you clear guidance on materials, methods, and quality checks so you can talk to suppliers with confidence. From laminating copper clad cores to finishing and testing, we show how great boards are built.

#1 Material Selection and Lamination

Fabrication starts with choosing the dielectric and copper foil that fit electrical, thermal, and mechanical needs. Common choices include FR4 for general work, high Tg laminates for heat, and low loss PTFE or hydrocarbon ceramics for radio frequency designs. Sheets and prepregs are stacked to form cores and sublaminates, then pressed under heat and pressure so resin flows and cures. Controlled lamination prevents voids, resin starvation, and excessive glass weave skew. Registration targets and lamination profiles are tuned for multilayer count and copper weight. Good stackup planning enables impedance control, flatness, and reliability in reflow and field use.

#2 Inner Layer Imaging and Etching

Inner layers carry the buried traces that define power distribution and high speed signals. The copper on each core is cleaned, coated with photoresist, and exposed with laser direct imaging or phototools. Developing removes unexposed resist so etchant can dissolve copper and leave the desired pattern. Critical controls include line width compensation for etch bias, undercut prevention, and cleanroom handling to reduce defects. Automated optical inspection compares each layer to design data to catch nicks or opens early. After inspection, resist is stripped and copper is passivated to prevent oxidation before lamination.

#3 Drilling and Via Formation

Holes form plated through paths and mechanical features such as tooling and press fit pins. CNC drills are used for standard diameters, while lasers create microvias in high density interconnect designs. Stack management, entry materials, and optimized feeds and speeds reduce burrs and smear. Desmear and plasma etch remove resin residue and roughen the hole wall to promote copper adhesion. Aspect ratio limits and pad design determine reliable plating and yield. Backdrilling can remove unused stubs for cleaner signal integrity. Proper drilling data, hit verification, and bit life monitoring keep accuracy and throughput high.

#4 Electroless and Electrolytic Copper Plating

To make vias conductive, a thin catalytic layer is deposited using electroless copper, creating a seed across hole walls and surfaces. This is followed by electrolytic copper plating to build thickness for current carrying and reliability. Parameters such as bath chemistry, agitation, current density, and temperature control throwing power and uniformity. Pulse plating helps fill microvias without voids. Periodic checks of thickness in holes and on surfaces ensure compliance with design and standards. After plating, a microetch refreshes the copper for subsequent resist application and imaging on the outer layers.

#5 Outer Layer Imaging and Pattern Plating

Outer layers are patterned to create final traces and pads. Photoresist is applied and imaged as before, but now pattern plating deposits copper only where traces and pads will remain, followed by a protective tin cap. Unwanted copper is etched away, using the tin as resist, then the tin is stripped. Accurate compensation for etch and plating growth preserves controlled impedance. Cleanroom discipline, antistatic handling, and frequent visual checks reduce shorts and opens. Advanced lines use direct imaging for fine features and tighter registration across large panels.

#6 Solder Mask Application and Imaging

Solder mask insulates copper, prevents bridging during assembly, and improves creepage for safety. Liquid photoimageable materials are common, applied by curtain coating or spray for uniform coverage. After tack drying, imaging defines openings for pads, test points, and fiducials, followed by development, full cure, and gloss control. Color selection can influence inspection contrast and brand presentation. Key metrics include mask to copper clearance, tenting quality over vias, and resistance to flux chemistries. Well aligned solder mask improves paste printing, rework visibility, and long term protection in harsh environments.

#7 Surface Finish for Solderability and Protection

Surface finish preserves copper and offers a solderable interface matched to assembly processes. Popular options include electroless nickel immersion gold for fine pitch pads, immersion silver for cost effective flatness, organic solderability preservatives for low cost, and hot air solder leveling for robust through hole work. Selection depends on shelf life, wire bonding, corrosion risk, and budget. Thickness control, cleanliness, and microcontamination checks prevent solderability defects. Compatibility with the chosen paste and flux is verified in sample builds before volume release. Suppliers also monitor nickel phosphorus content and gold thickness to avoid brittle joints and black pad.

#8 Silkscreen, Fabrication Markings, and Serialization

Legible markings reduce assembly errors and speed troubleshooting. Silkscreen ink or digital legend printing identifies reference designators, polarity marks, test points, and revision codes. Fabrication notes add lot identifiers, material codes, and stackup references for traceability. Barcodes or QR codes enable automated tracking through assembly and field service. Clear keepouts maintain spacing from pads and mask openings to prevent contamination. High contrast text, standardized symbols, and consistent placement aid human and machine vision during inspection and repair. Designers should specify minimal font size, stroke width, and locations so that legends remain readable after solder mask cure and reflow.

#9 Electrical Test, Dimensional Inspection, and Reliability Screening

Each board is verified against the netlist using flying probe or bed of nails testers to catch opens and shorts. Dimensional checks confirm hole sizes, board outline, and controlled depth features. Cross sectioning samples reveal plating thickness, resin content, and voids. Thermal stress, solder float, and ion chromatography may be used to qualify materials and processes. Statistical process control highlights trends before they become yield loss. Documented accept criteria aligned with industry standards give customers confidence and speed incoming inspection. Failures are analyzed with microsections and X ray so root causes can be corrected quickly.

#10 Panelization, Routing, and Final Quality Assurance

Efficient panelization maximizes yield and reduces handling damage. Tabs with mouse bites or v cuts define depanelization strategy that matches assembly equipment. Routing, scoring, and edge finishing produce clean edges for safe handling. Final cleaning removes residues, and ionic contamination levels are checked to prevent corrosion. Packaging with humidity control, corner protection, and clear labels preserves finish and traceability in transit. A final quality review confirms documents, certificates, and test data so that boards arrive ready for assembly without surprises. Customer feedback from first builds is looped back into panel design and quality checks for continuous improvement.