Forging shapes metal using compressive forces to refine grain flow, raise fatigue strength, and produce reliable parts for aerospace, automotive, energy, and tooling. This guide explains fundamentals and practical choices that engineers, buyers, and students can use when matching parts to processes. We compare stock reduction, die design, thermal windows, and cost trade offs, then show where each process excels by size, geometry, and volume. From large shafts to tiny fasteners, the Top 10 Metal Forging Methods Open Die Closed Die and Ring Rolling provide a clear framework to select equipment, materials, and quality controls that deliver strength, precision, and value.

#1 Open Die Forging for Large Simple Shapes

Open die forging uses flat or contoured dies to compress heated billets into bars, disks, hollows, and shafts while the workpiece is manipulated between blows. The low tooling complexity suits large parts, short runs, and development work. Engineers value refined grain flow, sound centers, and freedom to upset or draw for tailored properties. Thermal control matters: soak to uniform temperature, limit surface cooling, and plan reduction per pass to avoid laps. Specify oversize for final machining and ultrasonic inspection on critical sections. For turbines, heavy equipment, and pressure vessels, open die delivers robust, traceable stock with predictable mechanical performance.

#2 Closed Die Forging for Near Net Repeatability

Closed die forging forms near net shapes inside matched impressions, combining flash land, blocker, and finisher cavities to control flow. It excels for medium to high volumes where repeatability and strong grain alignment are crucial. Success depends on accurate billet volume, preform design, and generous radii for fill without flow separation. Use parting lines that simplify ejection and machining. Warm or hot windows enhance ductility, while controlled lubrication reduces die wear. Expect tighter tolerances than open die and shorter machining time. Aerospace fittings, connecting rods, and gear blanks gain high strength and consistent geometry with cost effective cycle times.

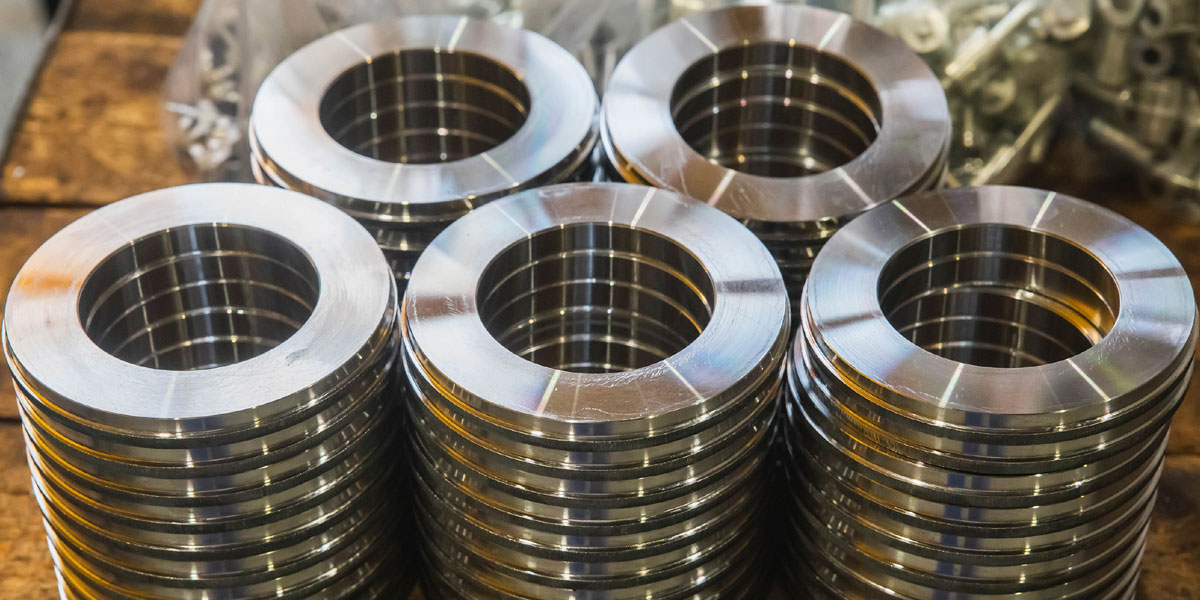

#3 Ring Rolling for Seamless Circular Strength

Ring rolling expands a pierced preform over a mandrel between driven rolls to create seamless rings with controlled wall and diameter. The method yields excellent circumferential grain flow and low material waste compared with machining from plate. Preform geometry, temperature, and reduction schedule are critical for stability and roundness. Rings can be profiled with flanges or steps, reducing downstream machining for bearings, flanges, and turbine casings. After rolling, normalize or quench and temper to lock properties. Specify ovality and wall variation limits, and include ultrasonic testing zones. Results are lightweight, strong, and economical for diameters from small to massive.

#4 Upset Forging for Heads and Local Enlargements

Upset forging increases cross section by compressing heated bar or wire along its axis to form heads, flanges, and enlarged sections. In headers, multi blow stations progressively shape fasteners with excellent fiber continuity. Key variables are buckling control, end conditioning, and precise cut length. Provide chamfers and fillets to guide flow, and limit length to diameter ratios to avoid fold defects. Upsetting is highly productive for bolts, valves, and stepped shafts, especially with induction heating. Cooling practice and in line inspection help prevent quench cracks and mix ups. The outcome is repeatable geometry with high shear and tensile performance.

#5 Roll Forging for Tapers and Preforms

Roll forging reduces section and creates tapers, blades, and leaf spring preforms by passing heated stock through grooved rolls. It offers continuous flow, short cycle time, and minimal scale compared with repeated blows. Proper draft angles, bite control, and synchronized speed prevent slipping and fishtails. Preform design feeds subsequent closed die or ring rolling stages, cutting flash and machining allowances. Because deformation is distributed, roll forging achieves fine surface finish and uniform strain. Monitor temperature loss along the pass schedule and apply suitable lubricants. Applications include spanners, axles, and hand tool blanks where consistency and throughput are vital.

#6 Swaging and Radial Forging for Concentric Reductions

Swaging and radial forging use oscillating dies to hammer a rotating bar or tube, progressively reducing diameter or forming internal profiles with a mandrel. The process maintains concentricity and smooth finishes without chips, which is valuable for driveshafts, gun barrels, and medical tubes. Feed rate, reduction per pass, and die geometry govern surface quality and residual stress. Lubrication and precise guide alignment prevent chatter. Swaging can close tubes or create stepped contours that later receive threads or splines. Because deformation is incremental, material work hardening can be managed with interpass reheating or annealing to achieve repeatable mechanical properties.

#7 Cold Forging and Cold Heading for High Volumes

Cold forging shapes steel or aluminum at room temperature for superior surface finish, dimensional control, and work hardening. Cold heading machines can produce millions of fasteners with exceptional consistency. Success relies on spheroidized wire, accurate lubrication, and generous radii to prevent cracking. Flow is limited, so designs must respect low strain capacity and avoid sharp transitions. Near net shapes reduce machining chips, and residual compressive stresses can improve fatigue. Secondary operations like piercing, thread rolling, and heat treatment complete the part. When volumes are high and tolerances are tight, cold forging delivers cost leadership with strong mechanical properties.

#8 Warm and Hot Die Forging with Isothermal Control

Warm and hot die forging extend formability for alloys that crack when cold, while isothermal control aligns die and billet temperatures to minimize gradients and flow stress. The combination enables thin webs, sharp bosses, and complex ribs in titanium, nickel, and aluminum alloys. Tool steels require robust coatings and steady lubrication to limit adhesion. Thermal cycles must balance grain growth against die life, often using rapid reheat and precise dwell. Process modeling predicts fill and risk zones, guiding preform changes. The payoff is accurate geometry with reduced press loads, lower rejection rates, and improved microstructure for demanding service.

#9 Precision Near Net Shape Forging for Minimal Machining

Precision forging targets minimal machining by controlling flash, draft, and die deflection to achieve tight envelopes directly off the press. It uses blocker and finisher sequences, calibrated billets, and rigid dies with predictable elastic recovery. Features like bosses, ribs, and split lines are positioned to aid ejection and reduce tool wear. Statistical process control on load, stroke, and temperature maintains dimensional capability. When combined with roll forged or upset preforms, material yield is high and cycle time short. Applications include gear shapes, turbine blades, and orthopedic implants that benefit from uniform grain flow and excellent repeatability.

#10 Powder Forging and Hybrid Routes for Complex Forms

Powder forging consolidates a sintered preform under high temperature and pressure to close porosity and create wrought level properties in complex shapes. It offers excellent material utilization for gears, sprockets, and asymmetric forms that are difficult in conventional dies. Design freedom includes internal features and controlled density gradients before consolidation. Hybrid routes combine additive preforms with finish forging to align grains and correct surfaces. Careful atmosphere control, preform strength, and tooling support prevent cracking. After forging, carbon control and heat treatment refine hardness and toughness. The method blends net shape complexity with the strength of fully forged material.