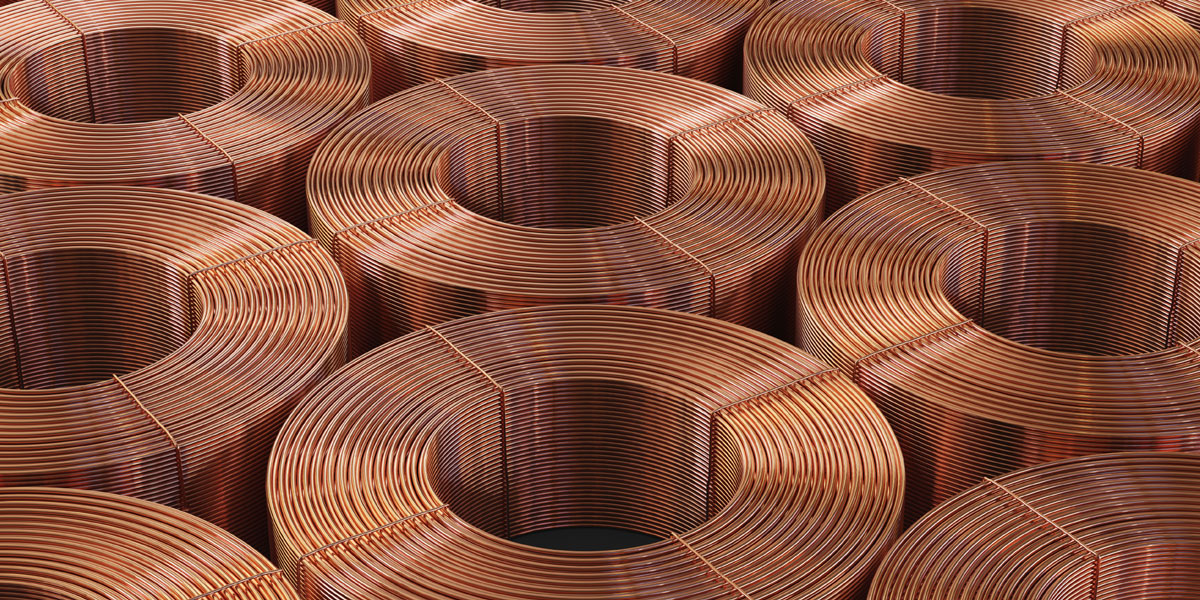

Copper and brass are the backbone of electrical hardware because they combine high electrical conductivity with formability, corrosion resistance, and stable spring properties. In this guide, we explain the Top 10 Copper and Brass Forming Processes for Electrical Components so beginners and experienced engineers can choose the right route from strip to finished part. You will learn how each process shapes geometry, controls grain structure, and manages residual stresses that influence contact resistance, fatigue life, and dimensional stability. We also highlight tooling considerations, tolerances, and cost levers to help you balance performance with manufacturability across volumes ranging from prototypes to millions of pieces.

#1 Progressive stamping for terminals and contact springs

Progressive stamping turns coil strip into precise terminals, sockets, and contact springs in a single press stroke per station. Blanking, forming, and piercing happen sequentially on a carrier strip, which maintains pitch for accurate feed and part location. Material selection focuses on tempers like C11000 annealed for conductivity or C51000 phosphor bronze spring tempers for force retention. Key controls include burr direction, punch to die clearance, and slug evacuation to avoid galling. Deburring, stress relief anneal, and selective plating such as nickel under gold reduce contact resistance. Use progressive stamping for high volume parts with tight repeatability and low cost per piece.

#2 Deep drawing and redrawing for shields and cups

Deep drawing converts flat copper or brass blanks into cups, cans, and RF shields with smooth radii and uniform walls. Success depends on blank holder pressure, draw ratio, and well polished radii to prevent tearing and wrinkling. Fully annealed tempers and lubricants with high film strength support material flow, while intermediate anneals restore ductility before redrawing. Ironing can thin walls intentionally for weight savings without compromising strength if grains are refined by controlled cooling. Trim operations set final heights, then beading or curling strengthens edges. Choose deep drawing when seamless geometry improves electromagnetic shielding, dielectric spacing, and leak tightness in sensitive assemblies.

#3 Precision bending, coining, and embossing

Many electrical contacts require crisp bends, coined tips, and embossed features to control spring force and mating wear. Air bending with CNC press brakes is flexible, while bottoming or coining gives tight angle control and reduces springback in brasses and bronzes. Embossing stiffens thin sections without extra mass and can create strain reliefs or locator beads. Use generous inside radii relative to thickness for conductive coppers to prevent cracking, and apply neutral axis compensation in flat patterns. After forming, a low temperature stress relief stabilizes angles before plating. These operations suit busbar jumpers, relay contacts, motor brush holders, and battery tabs with defined geometry.

#4 Cold heading and upset forging for lugs and fasteners

Cold heading gathers material to create heads, studs, and terminal features from wire or rod without machining chips. Brass alloys like C36000 and C35300 offer excellent heading response, while oxygen free copper supports electrical lugs that need high conductivity. Process windows depend on die radii, lubricant film integrity, and temperature rise control to avoid adhesion. Subsequent pierce or thread rolling adds functionality with high fatigue strength. Compared with machining, heading delivers faster cycle times and better fiber flow for improved mechanical performance. Use cold heading and upset forging when you need robust cable lugs, threaded terminals, and captive hardware at scale.

#5 Extrusion and cold drawing for busbars and pins

Extrusion produces solid or hollow copper and brass profiles with consistent grain flow for current carrying parts. Hot extrusion sets the initial shape, then cold drawing tightens tolerances and improves surface finish for pins and sockets. Straightness, concentricity, and edge radii control resistance heating and insertion forces in connectors. Subsequent operations like knurling, micro grooving, and cut to length help press fit retention. Anneal cycles are tuned to maintain conductivity while meeting hardness targets such as half hard for formability or hard for wear. Choose this route for custom busbar sections, high strength contact pins, and heat spreading interposers requiring uniform properties.

#6 Roll forming and edge radiusing for busbars

Roll forming bends long copper strip through successive rolls to create accurate offsets, channels, and complex busbar shapes. It excels for large panels and switchgear where cumulative angle accuracy and flatness reduce assembly time. Edge radiusing removes sharp corners that concentrate electric fields and plating stress, while punched slots are introduced before forming to control distortion. For multilayer bars, adhesive or diffusion bonded laminates reduce AC losses by limiting eddy currents. Post form anneal can relieve stress to stabilize dimensions. Use roll forming when you need repeatable busbar geometries, controlled edge quality, and efficient throughput from coil to finished assemblies.

#7 Swaging and crimping for cables and terminations

Swaging and crimping create reliable mechanical and electrical bonds between conductors and terminals without solder. Controlled plastic deformation collapses barrel walls into strands, excluding air and minimizing contact resistance. Tooling geometry and crimp height are validated by pull tests and microsections to verify full strand engagement and correct compression. Annealed copper barrels swage uniformly, while tin or silver plating improves corrosion resistance. Strain relief crimp wings and insulation supports prevent fretting during vibration. Choose swaging and crimping for field serviceable ends, battery cables, motor leads, and high current lugs where repeatable low resistance and speed are essential.

#8 Metal spinning and flow forming for thin shells

Metal spinning forms axisymmetric copper and brass shells by pressing a roller against a rotating blank on a mandrel. It is ideal for EMI shields, instrument housings, and transformer end bells where seamless walls improve reliability. Flow forming extends the idea with greater deformation to reach thinner walls while keeping concentricity. Key controls include tool nose radius, mandrel surface, and incremental passes to prevent orange peel and tearing. Intermediate anneals reset work hardening in oxygen free copper for deep reductions. Spun parts can be trimmed, beaded, and lightly planished before plating, yielding smooth contours that assemble cleanly with minimal finishing.

#9 Sheet hydroforming for complex enclosures

Sheet hydroforming uses a bladder or fluid pressure to push copper or brass against a single die, creating deep, smooth shapes with minimal tooling. It is excellent for prototypes and medium volumes when surface finish is critical and draw beads are undesirable. Uniform pressure reduces thinning at corners compared with rigid dies, and wrinkling is controlled by blank holder force. Annealed tempers improve draw depth, while calibrated pressure cycles limit work hardening and residual stress. After forming, edges are trimmed and holes pierced to maintain datum accuracy. Consider hydroforming when you need fast iteration and hard to draw contours on EMI shields and housings.

#10 Incremental sheet forming for agile prototyping

Incremental sheet forming uses a CNC toolpath to locally deform copper or brass without matched dies, enabling fast trials of complex geometries. A hemispherical stylus follows layers down to target depth, building walls gradually while clamps hold the blank. Small step downs reduce thinning and surface scarring, and tool lubrication improves finish. The method suits low volume custom contacts, RF cavities, and shields required during development when tooling budgets are limited. Mechanical properties reflect significant work hardening, so a final anneal may be scheduled before trimming. Select incremental forming to shorten design cycles and validate fit before investing in progressive dies or hard tooling.