Electrical equipment performs best when materials are matched to the job, since conductivity, stability, and cost set real limits on current, heat, and lifetime. This guide explores the Top 10 Conductive Materials For Electrical Equipment Manufacturing And Their Best Use Cases to help learners link properties to practical design choices. From classic metals that carry heavy loads to emerging carbon based conductors used in tiny sensors, we compare conductivity, corrosion resistance, solderability, fatigue life, weight, and thermal behavior. You will gain a clear sense of trade offs that guide engineers in cables, connectors, busbars, motors, sensors, and printed circuits.

#1 Copper

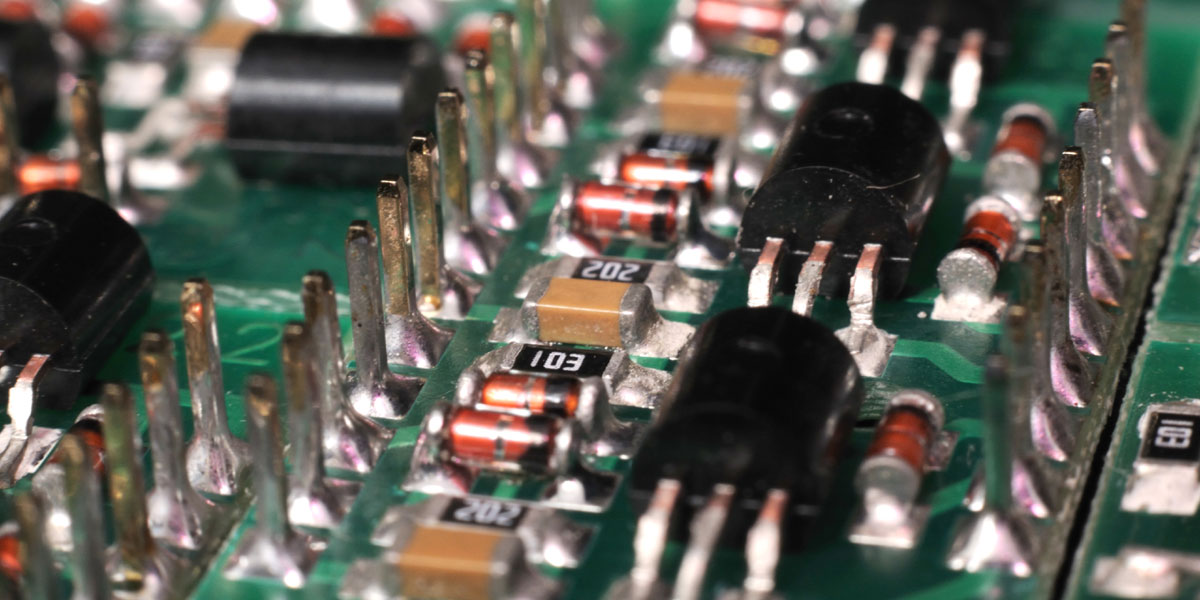

Copper remains the industrial benchmark for electrical conductivity combined with manufacturability. It offers low resistivity, good thermal conduction, excellent solderability, and broad alloy families that balance strength with ductility. Typical use cases include power cables, busbars, transformer windings, PCB traces, slip rings, rotor bars, and high performance heat spreaders. In connectors, oxygen free copper improves fatigue life where repeated mating cycles occur. Tin or silver plating resists oxidation without raising cost too much. Designers watch cross sectional area, grain direction, and anneal state to control losses and mechanical stress, especially in high current or high vibration environments.

#2 Aluminum

Aluminum delivers a strong conductivity to weight ratio that beats copper on mass critical designs. It has lower density, reasonable cost, and forms a protective oxide that resists many environments. Best uses include overhead power lines, large bus ducts, motor housings that double as heatsinks, and high volume enclosures that require light weight. Crimping and surface preparation matter because the oxide can raise contact resistance. Alloys with magnesium or silicon provide better strength for extruded busbars. Engineers oversize conductors to match copper performance and select compatible lugs and pastes so galvanic coupling with copper or steel does not accelerate corrosion.

#3 Silver

Silver is the most conductive metal and shines where very low resistance and stable contact performance are essential. It is frequently used as a thin plating on contacts, relays, high current switches, RF connectors, and precision slip rings. In thick film pastes, silver enables reliable printed resistors and antennae on ceramics or glass. While bulk silver is costly and soft, micro thin coatings provide high performance at controlled cost. Design teams manage tarnish with proper lubricants and use silver nickel or silver palladium contact materials to improve wear, arc resistance, and sulfide tolerance in polluted atmospheres.

#4 Gold

Gold resists corrosion and maintains low contact resistance even after long storage or harsh humidity cycles. It is widely specified for signal level connectors, chip package pads, edge fingers, and measurement grade interconnects where data integrity is critical. Hard gold over a nickel barrier limits pore corrosion and improves wear during repeated insertions. Because gold is expensive, designers apply it selectively, keeping thickness just high enough for reliability. Gold wire bonding remains a mature interconnect for certain semiconductors, although copper and aluminum also compete. Careful underplating and cleanliness are vital to avoid intermetallic growth and to ensure stable millivolt level performance.

#5 Nickel

Nickel provides moderate conductivity with strong corrosion resistance, magnetic properties, and excellent diffusion barrier behavior. It is a common underplate beneath gold or silver to stop base metal migration and to improve wear. Nickel alloys power heating elements, battery tabs, and sensor packages that see elevated temperatures. Electroless nickel offers uniform thickness in complex geometries, while electrolytic nickel suits higher throughput lines. In fuel cells and alkaline battery hardware, nickel resists attack and supports repeated cycling. Designers consider ferromagnetism in sensitive instruments and use low phosphorus electroless variants when solderability and lower brittleness are important in assembly.

#6 Brass

Brass combines acceptable conductivity with high machinability and spring characteristics, which makes it a connector workhorse. It is used for terminals, sockets, contact cages, threaded inserts, and precision turned parts that must hold tight tolerances. Lead free brass grades support compliance requirements and improve health safety in assembly areas. Plating with tin, nickel, or gold tunes contact resistance and wear life. Compared with pure copper, brass maintains shape under load and resists creep in clamped joints. Engineers choose alloy and temper to balance formability with stress relaxation so fasteners and press fit pins remain stable over long service intervals.

#7 Phosphor Bronze

Phosphor bronze offers higher strength and superior spring memory compared with brass, while keeping good conductivity. It excels in contact springs, battery clips, signal connectors, and reed switch components that require repeated elastic deflection. The small addition of phosphorus refines grain and improves wear. For harsh environments, tin plated phosphor bronze maintains contact performance when cycles and vibrations are numerous. Stampers appreciate its clean shearing and ability to hold sharp features at thin gauges. Designers specify grain direction and stress relief to control fatigue, and they model contact force carefully to avoid micro fretting that raises resistance.

#8 Graphene

Graphene delivers exceptional intrinsic conductivity and very high carrier mobility at nanoscale thickness, which enables innovative interconnects and sensors. It is used in transparent electrodes for touch panels, flexible heaters, and electromagnetic shielding films. In batteries and supercapacitors, graphene networks enhance current distribution and reduce internal resistance. For industrial adoption, layer quality, substrate choice, and transfer methods determine repeatability. Engineers integrate graphene with polymers to form printable composites for wearable electronics. While bulk metal still rules power paths, graphene is valuable where thin, flexible, and optically clear conductors are required, and where weight and bending cycles dominate design limits.

#9 Carbon Nanotubes

Carbon nanotubes form conductive networks with remarkable strength to weight ratios and resilience under bending, which suits flexible electronics. They appear in antistatic coatings, strain sensors, EMI shielding gaskets, and printable inks for lightweight interconnects. Aligned nanotube films enable transparent conductors that rival indium tin oxide while withstanding repeated flexing. Processing chooses dispersion quality, tube length, and functionalization to tune sheet resistance and adhesion. In power devices, nanotubes serve as thermal spreaders and as field emission sources. Manufacturers manage safety and purity carefully, and they combine nanotubes with silver flakes or graphene to reach target performance at realistic cost.

#10 Conductive Polymers

Conductive polymers such as PEDOT and polyaniline provide moderate conductivity with low density, flexibility, and solution processability. They enable antistatic layers, capacitive touch sensors, organic LEDs, and conformal coatings that prevent charge buildup. Printed electronics use them for traces on paper, textiles, and plastics where traditional plating is impractical. Their conductivity depends on doping level, moisture, and temperature, so packaging and overcoats control stability. Hybrid stacks that include silver or carbon elements carry higher currents while the polymer provides flexibility and adhesion. Engineers value room temperature processing for rapid prototyping and for roll to roll manufacturing in large area smart labels.