Aluminum underpins transportation, construction, packaging, power, and consumer products because it is light, strong, and highly recyclable. This guide unpacks the Top 10 Aluminum Manufacturing Methods from Smelting to Fabrication so learners at every level can connect raw materials, core processes, and end uses with clarity. We begin with refining and smelting, move through solidification and deformation routes, and finish with component making, joining, finishing, and recycling. Each method explains the purpose, essential science, common equipment, and quality controls. Read it sequentially to see the value chain flow, or dip into sections to compare alternatives that balance cost, performance, throughput, and sustainability.

#1 Bayer refining of bauxite to alumina

Bayer refining converts mined bauxite into smelter grade alumina through digestion, clarification, precipitation, and calcination. Caustic soda dissolves gibbsite and boehmite at elevated temperature and pressure, leaving red mud residues that must be carefully managed. Seed crystals guide precipitation of aluminum hydroxide with controlled particle size, which is then washed and calcined to produce high purity alumina. Key controls include caustic concentration, temperature profiles, residence time, and impurity removal for silica, iron, and titanium. Modern plants optimize steam recovery, caustic regeneration, and residue storage stability. The resulting alumina defines smelter energy demand, bath chemistry, and metal cleanliness downstream.

#2 Hall Heroult primary aluminum smelting

Hall Heroult cells dissolve alumina in a molten cryolite based electrolyte and reduce it to liquid aluminum using direct current. Carbon anodes supply carbon to form carbon dioxide, so precise alumina feeding avoids anode effects that increase voltage and emissions. Prebaked anodes and point feeders stabilize bath composition while magnetic compensation reduces wave induced shorting. Bath temperature, alumina concentration, and cell voltage are balanced to lower specific energy consumption while protecting lining life. Molten metal is regularly tapped to crucibles, then transferred to holding furnaces for alloying. Continuous improvement targets lower per ton energy, fluorides capture, and automation.

#3 Melt treatment and direct chill casting

After tapping, furnaces adjust composition using master alloys and fluxes. Melt treatment removes dissolved hydrogen and inclusions through rotary degassing, argon injection, and ceramic foam filtration. Direct chill casting solidifies aluminum into billets, slabs, or large ingots by pouring metal into a water cooled mold while spraying water onto the emerging shell. Metallurgists control casting speed, metal head, and grain refinement additions to prevent hot tears and centerline segregation while achieving uniform microstructure. Homogenization heat treatment follows to dissolve segregation and spheroidize intermetallics, improving extrudability or rolling response. Precise logs and slabs become the feed for deformation processes.

#4 Twin roll and continuous strip casting

Twin roll casting produces near net thickness strip by solidifying aluminum between two internally cooled counter rotating rolls. This method compresses casting and hot rolling into a single step, enabling rapid production of sheet feedstock for can body, automotive heat exchangers, and foil stock. Key variables include roll gap, metal superheat, nozzle design, and lubricant management to control centerline segregation, surface quality, and texture. Variants like belt or wheel based continuous casting offer different thickness ranges and alloy capabilities. The value lies in reduced capital, lower energy per ton, and faster alloy changeovers compared with conventional slab routes.

#5 Hot and cold rolling of plate, sheet, and foil

Rolling transforms cast slabs or strip into plate, sheet, and foil with controlled thickness, texture, and flatness. Hot rolling above recrystallization temperature breaks down cast structure and sets gauge for subsequent passes. Cold rolling increases strength through work hardening while refining surface finish and dimensional accuracy. Mills employ automatic gauge control, shape meters, coolant chemistry control, and coiling strategies to prevent wavy edges and chatter marks. Heat treatable alloys are solution treated and quenched after hot rolling when required. Foil mills achieve micrometer level gauges by tandem passes and double rolling before final separation and annealing.

#6 Aluminum extrusion for complex profiles

Extrusion forces heated billets through precision dies to create long profiles with complex cross sections for frames, heat sinks, rails, and structural members. Process control focuses on billet temperature, ram speed, container alignment, and die design to avoid surface tearing, pick up, and dimensional drift. Online quenching and stretch straightening stabilize properties and control residual stress. Age hardening alloys receive artificial aging to reach target tempers that balance strength with toughness and corrosion performance. Multi hole dies enable high throughput for small profiles, while porthole technology joins metal streams around mandrels. Anodizing or powder coating completes appearance and durability.

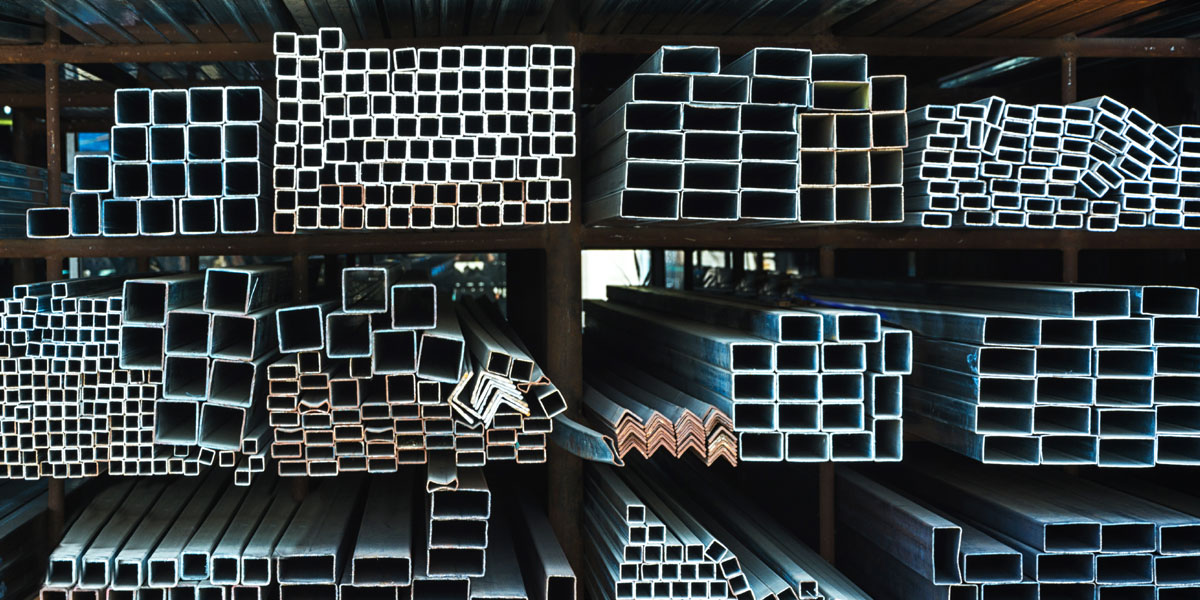

#7 Casting of near net shape components

Component casting covers sand, gravity permanent mold, low pressure, and high pressure die casting, each tuned to alloy, size, and tolerance needs. Sand casting suits large or intricate geometries with moderate precision. Permanent mold improves surface finish and consistency. Low pressure casting offers calm fill for wheels and safety critical parts. High pressure die casting delivers thin walls and high productivity for housings and e mobility structures, often using silicon rich alloys. Soundness depends on gating, venting, vacuum assistance, and thermal management of dies. Melt cleanliness, porosity control, and heat treatment compatibility govern fatigue and leak tightness.

#8 Powder metallurgy and additive manufacturing

Powder metallurgy compacts aluminum powders then sinters or hot consolidates to create parts with tailored porosity or dispersion strengthened properties. Gas atomized powders enable uniform chemistry and spherical morphology for flow. Additive manufacturing routes such as laser powder bed fusion and directed energy deposition build complex lightweight lattices and conformal cooling channels not feasible by machining. Success depends on powder size distribution, moisture control, oxygen pickup, scan strategies, and hot isostatic pressing for defect closure. Post build heat treatment stabilizes microstructure and relieves stresses. These routes support rapid iteration for aerospace, tooling, and thermal management innovations.

#9 Heat treatment and thermomechanical strengthening

Heat treatable aluminum alloys rely on solution treatment to dissolve strengthening phases, rapid quenching to retain a supersaturated solid solution, and controlled aging to precipitate fine particles that impede dislocation motion. Process windows are tight to prevent distortion, quench sensitivity defects, or over aging. Non heat treatable alloys gain strength through cold work and strain hardening, then partial anneals tailor formability. Property verification uses hardness mapping, conductivity checks, and tensile testing to confirm temper. Precise furnace uniformity surveys, quench agitation control, and racking design ensure repeatability. Correct temper selection drives fatigue resistance, bendability, and crash energy absorption.

#10 Fabrication, joining, finishing, and recycling

Final value emerges through forming, machining, joining, finishing, and circular recycling. Forming methods include stretch forming, deep drawing, hydroforming, and spin forming that respect anisotropy and springback. Joining options span gas tungsten arc welding, gas metal arc welding, resistance spot welding, and friction stir welding that produces low defect solid state seams. Adhesive bonding with surface preparation combines dissimilar materials. Finishes include mechanical polishing, conversion coating, anodizing, and powder coating to enhance corrosion resistance and aesthetics. Recycling closes the loop by remelting process scrap and post consumer metal with fraction of primary energy, reducing cost and carbon footprint.