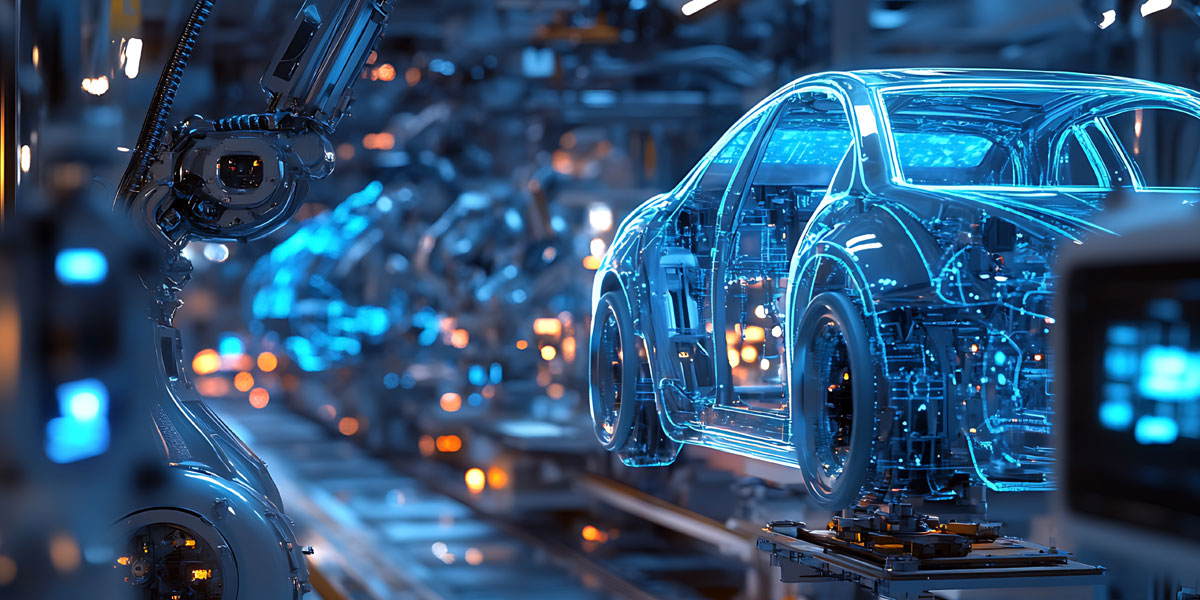

Automotive body and chassis parts are shaped by precise metalworking that balances speed, accuracy, and material behavior. In this guide, we present the Top 10 Automotive Stamping and Press Forming Processes so you can understand how flat sheet becomes safe, lightweight components. Each process transforms coil or blanks into parts with tight tolerances while controlling springback, thinning, and surface finish. You will learn where each method fits, what tooling looks like, and how sensors and simulation help teams predict defects before a die closes. From high strength steels to aluminum, the focus is practical and clear so beginners and experts both gain value.

#1 Blanking and Shearing

The journey often starts by cutting flat sheet into accurately sized blanks. High speed presses use sharp punches and dies to separate material along clean lines while minimizing burr and rollover. Engineers set clearance to match material thickness and hardness, which controls edge quality and punch force. Proper lubrication protects tools and improves part flatness. Nested layouts reduce scrap, while coil feeders and straighteners ensure consistent pitch. Quality teams inspect sheared edges for burnish, fracture zone, and burr height so downstream drawing, bending, or piercing proceeds without cracks or dimensional drift.

#2 Piercing and Notching

After blanking, many parts require holes, slots, and cutouts for fasteners and assembly location. Piercing adds these features, and notching removes corners to guide later forming. Die design uses pilots to hold position, stripper plates to control part release, and hardened tool steels for durability. Small holes risk punch breakage, so engineers watch the ratio of hole diameter to sheet thickness. Slug retention and vacuum removal keep dies clean. Inline vision checks hole size, roundness, and true position so weld fixtures and robots can locate every panel with repeatable precision. Regular regrinds help hold dimensions stable.

#3 Bending and Flanging

Bending creates angular forms and flanges that stiffen edges for welding, hemming, and assembly. Dies use radii that are large enough to limit cracking, especially with advanced high strength steels. Springback is managed through overbending, restrike stations, or add on cams that correct angles. Bead features can lock material flow and stabilize edges. Flanging dies create upstands and return flanges that support spot welds and sealants around openings. Process capability depends on consistent lubrication, binder pressure, and part locating pins that prevent shifting and protect the critical datum scheme. Simulation predicts angle variation and guides early die tuning.

#4 Deep Drawing

Deep drawing pulls sheet into a die cavity using a punch and controlled blank holder pressure to make cups, doors, and complex closures. Success depends on balancing friction, draw bead geometry, and radii so material flows without wrinkling or tearing. Engineers map thinning with forming limit diagrams and tune binder pressure across zones. For dual phase steel or aluminum, surface coatings and lubricants reduce galling. Multiple draw stages with intermediate anneal may be needed for severe shapes. Accurate trimming after each stage preserves locating edges and avoids split propagation. Redraw operations stabilize walls so final geometry meets targets.

#5 Progressive Die Stamping

Progressive dies combine blanking, piercing, forming, and trimming across many stations in one press stroke sequence. A strip advances station by station using pilots for registration, building the part gradually until final cut off. This approach offers high throughput and consistent quality for brackets, reinforcements, and small body hardware. Tooling includes lifters, cams, and nitrogen springs to control material. Sensors verify feed length and detect misfeeds to prevent tool damage. Scrap carriers and slug management keep dies reliable. Dimensional checks at key stages monitor drift and guide preventive maintenance. Modular stations shorten downtime to keep pace with body shop demand.

#6 Transfer Press Forming

Transfer presses move individual blanks between multiple dies using synchronized fingers or servo rails. Unlike progressive dies, the part detaches from the strip, which allows larger draws, undercuts, and reorientation between stations. This flexibility suits large structural parts such as floor pans and inner panels. Engineers design the transfer motion to avoid part collisions and to support edges during lift. Sensors confirm hand off positions. Material flow is tuned with draw beads and variable binder pressure across stations. Accurate timing protects surfaces and reduces noise. It can reduce weld counts by enabling one piece geometries.

#7 Coining and Embossing

Coining compresses material locally to sharpen edges, define logos, or set precise thickness for functional interfaces. Embossing raises or recesses patterns that add stiffness and guide adhesive flow. Both processes demand high press tonnage and hard tool steels to resist wear. Lubricant selection prevents sticking and protects surface finish for visible panels. Engineers consider flow restriction to avoid unintended thinning around the feature. Gauges and three dimensional scans verify relief height and flatness after release. Die temperatures and cycle timing are controlled tightly for repeatable results. Process control on feature height and depth protects function after paint bake.

#8 Hydroforming

Hydroforming replaces a rigid die half with pressurized fluid to push sheet against a shaped cavity, creating smooth forms with reduced wrinkling. Uniform pressure helps distribute strain, enabling tight radii and variable depths that are difficult with conventional drawing. This suits aluminum closures and lightweight reinforcements. Tooling incorporates pressure seals, draw beads, and robust hydraulics. Cycle time is longer, so engineers apply it where geometry or weight reduction offsets the rate penalty. Pressure ramps are tuned to control thinning and avoid blowouts. Piercing under pressure can be integrated to save die hits.

#9 Hot Stamping Press Hardening

Hot stamping heats boron steel blanks to austenite temperature, transfers them quickly into a cooled die, and forms while quenching to achieve very high strength. The result is thin parts with exceptional crash energy management, used for pillars, door rings, and bumper beams. Success depends on furnace soak time, transfer speed, and die cooling flow that locks the martensitic transformation. Surface coatings prevent scale and reduce friction. Accurate temperature monitoring avoids soft spots and distortion. Post forming straightening may be minimal due to low springback. Laser trimming removes edges with precise, repeatable kerf control.

#10 Hemming and Seaming

Hemming folds an outer panel edge over an inner panel to create smooth, safe borders around doors, hoods, and decklids. It improves stiffness, appearance, and sealing performance. Seaming joins materials along a continuous edge on closures and pillars. The process uses pre hemming and final hemming with carefully designed radii to avoid paint cracks and waviness. Adhesives inside the hem add corrosion protection and bond strength. Fixtures control gap and flush, while cushion forces prevent imprinting. Roller hemming robots enable flexible paths for complex edges. Inline sensing tracks hem thickness so every closure meets targets.