Electronics power modern life, from smartphones to satellites, and the ways we build them keep evolving. This article explains the Top 10 Electronics Manufacturing Process Technologies in clear, structured language so beginners and advanced readers can both learn. You will discover how parts are placed, circuits are formed, chips are made, quality is checked, and sustainability goals are met. Each section highlights what the technology does, why it matters, and where it is used. Read through to understand the flow from raw materials to reliable products, and how precision, automation, and data help companies deliver safe, high performing electronics at scale.

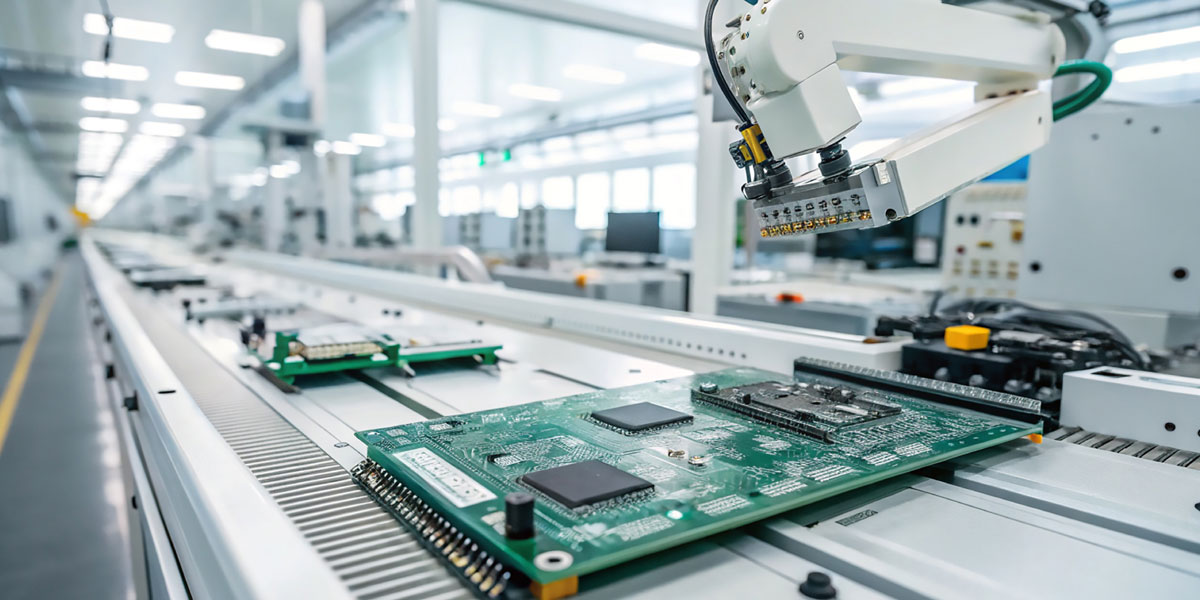

#1 Surface Mount Technology and PCB Assembly

Surface mount technology places miniature components directly onto the surface of printed circuit boards. The process starts with solder paste printing through laser cut stencils, followed by high speed pick and place machines that position resistors, capacitors, and integrated circuits. Reflow ovens then melt the solder to create durable joints. For double sided boards, the sequence repeats with careful thermal profiling. Selective soldering handles any through hole parts without stressing nearby components. Process control relies on paste inspection, placement force limits, and reflow temperature logs. The result is compact, robust assemblies that support dense layouts and high production throughput.

#2 Printed Circuit Board Fabrication

PCB fabrication transforms copper clad laminates into precise interconnects. Imaging defines fine traces with photoresist, while etching removes unneeded copper. Multilayer boards use lamination to stack inner layers with prepreg, then drilling forms vias and holes. Plating deposits copper to interconnect layers and reinforce hole walls. Solder mask protects conductors and supports soldering accuracy. Surface finishes like ENIG, immersion silver, and OSP preserve pad quality and planarity. Impedance control ensures high speed signal integrity through careful trace width and dielectric selection. Final electrical test screens for opens and shorts. Advanced shops add microvias, buried vias, and rigid flex constructions.

#3 Semiconductor Wafer Fabrication

Chip making begins with silicon wafers and uses repeated cycles of deposition, lithography, and etch to build transistors and interconnects. Thin films such as oxides, nitrides, and metals are deposited by chemical vapor deposition and physical vapor deposition for precise thickness control. Photolithography projects patterns using deep ultraviolet light and high numerical aperture optics. Dry plasma etching sculpts features with nanometer precision while endpoint detection protects underlying layers. Ion implantation sets dopant concentrations, followed by rapid thermal anneal to activate devices. Chemical mechanical polishing flattens surfaces between metal layers. Strict contamination control and defect monitoring enable high yield production.

#4 Advanced Packaging and System in Package

Packaging protects the die and brings signals to the outside world while minimizing electrical loss and thermal stress. Wire bond and flip chip connect the die to substrates, while wafer level chip scale packages reduce size and inductance. System in Package integrates multiple dies, passives, and sometimes antennas into one compact module. Fan out wafer level packaging redistributes contacts to support higher input and output counts without bulky substrates. Through silicon vias enable vertical stacking in three dimensional assemblies. Thermal interface materials, heat spreaders, and underfill resins manage reliability. The outcome is smaller, faster products with improved power efficiency.

#5 Additive and Printed Electronics

Additive techniques build circuits by depositing conductive, dielectric, and resistive inks only where needed. Inkjet, aerosol jet, and screen printing create traces on plastics, glass, textiles, and flexible films, enabling wearables and smart packaging. Conductive materials include silver flakes, copper nanoparticles, and emerging graphene based systems. Low temperature sintering and photonic curing allow processing on heat sensitive substrates. Printed antennas, sensors, and RFID tags reduce cost and expand form factors. Hybrid assembly combines printed interconnects with conventional silicon devices to balance performance and price. Design tools model sheet resistance and bend radius limits to ensure function during repeated flexing.

#6 Automation, Robotics, and Smart Factories

Modern electronics lines use robots, cobots, and automated guided vehicles to move materials, load feeders, and tend ovens. Machine vision aligns tiny parts, verifies polarities, and detects mispicks in real time. Manufacturing execution systems track work in progress, link serial numbers to process data, and enforce recipe control. Predictive maintenance algorithms analyze vibration, temperature, and cycle counts to schedule service before failures occur. Automated storage systems reduce kitting errors and ensure first in, first out inventory rotation. Digital twins simulate line performance to optimize bottlenecks. The result is higher throughput, consistent quality, safer workplaces, and faster responses to demand changes.

#7 Inspection, Metrology, and X Ray Analysis

Quality relies on measuring what matters at every step. Solder paste inspection checks volume, area, and height to prevent opens and bridges. After reflow, automated optical inspection flags missing parts, tombstones, and skew using rule based and machine learning classifiers. For hidden joints under ball grid arrays, automated X ray inspection reveals voiding, head in pillow defects, and insufficient wetting. Dimensional metrology verifies stencil apertures, board features, and component coplanarity. Process capability indices quantify stability over time. Correlation between inspection results and functional test outcomes drives continuous improvement. The best programs tune alarm thresholds to reduce false calls while catching real risks.

#8 Cleanliness, ESD Control, and Environmental Conditioning

Small residues can cause corrosion, leakage, and intermittent faults. Manufacturers manage ionic contamination through controlled cleaning, no clean flux selection, and cleanliness testing with ion chromatography. Electrostatic discharge control prevents latent damage by using grounded floors, wrist straps, dissipative work surfaces, and ionizers that neutralize charged particles. Humidity and temperature are regulated to protect materials such as solder paste and moisture sensitive devices. Cleanroom practices limit airborne particles during wafer processing and optical assembly. Material handling systems use dedicated trays and dry cabinets to maintain component integrity. Together, these controls protect fragile structures and safeguard long term reliability.

#9 Test Engineering and Reliability Qualification

Testing proves that assemblies behave as intended and remain robust in the field. In circuit test measures shorts, opens, and component values through bed of nails or flying probe access. Functional test powers the board and exercises interfaces, firmware, and safety features. Boundary scan leverages built in scan chains to probe complex nets without physical access. Reliability methods include highly accelerated stress screening, thermal cycling, humidity exposure, and vibration profiles to reveal early failures. Burn in tests expose latent defects before shipment. Statistical sampling plans balance cost and risk. Detailed failure analysis feeds root cause correction and strengthens future designs.

#10 Sustainability, Traceability, and Circular Manufacturing

Responsible manufacturing reduces waste while ensuring compliance. Lead free alloys and halogen free materials support safer products. Energy metering on ovens, compressors, and reflow zones identifies savings opportunities. Closed loop process control minimizes scrap and rework. Product passports and full traceability link each unit to materials, programs, and test records for faster recalls and regulatory assurance. Design for disassembly enables recovery of metals and modules at end of life. Take back programs and certified recyclers prevent landfill disposal. Life cycle assessment guides material and process choices. These practices align environmental goals with cost control and resilient supply chains.